SPEEDBOX-INS Options

| Product Datasheet |

The ultimate automotive testing and development instrument - with full vehicle attitude measurements referenced to time and GPS data, all at 200Hz.

The SPEEDBOX-INS range is our purpose designed automotive testing solution offering enhanced accuracy and flexibility over the standard SPEEDBOX product. The system comprises of a SPEEDBOX or SPEEDBOX MINI unit, coupled with an IMU sensor and antenna assembly mounted to the roof of the vehicle. The SPEEDBOX-INS system is used extensively by a number of international OEMs for testing and development. The system’s compact size, accuracy, and flexibility makes it ideal for a wide range of vehicle types and test applications. For most applications the INS Single Antenna will be the preferred option, however the stationary convergence of the INS Compact Dual Antenna enables “from cold” tests and use on slower moving vehicles.

SPEEDBOX-INS Single Antenna Features:

- Simple to install and use, no complex initialisation requirements. No figure of eights, no special convergence procedure.

- <10cm error for 100 to 0 km/h braking tests

- High precision automotive speed sensor – using tactical grade inertial (IMU) and GPS technology for an accurate and robust measurement.

- 200Hz on all channels, including acceleration, speed, distance, position, slip angle and vehicle attitude (roll, pitch and yaw)

- 0.08 degrees yaw, 0.04 degrees roll and pitch accuracy

- Robust to GPS outages, making it ideal for on highway use as well as at the test track

- 200Hz output on serial and CAN

- Optimised RF signal quality for reception in challenging environments

The SPEEDBOX-INS is our paramount industrial testing range. Using the complementary technologies of inertial and GPS systems - Using the best features of both with none of the drawbacks. The INS uses our complex algorithms and Kalman filtering to cross reference the GPS data with the inertial data, meaning that in difficult GPS conditions any short signal dropouts can be filled accurately by referencing the inertial data. This makes it ideal for real world road testing as well as test tracks.

The layout of the systems, with the GPS antennas and an IMU located in a single roof top assembly, means we can coordinate the data incredibly accurately with no "initialisation" phase required - Making it simple and quick to fit. It can be outputting data as soon as you get a GPS lock, fitted and ready for testing in a few minutes.

What can the INS option measure?

The INS sensor assembly is connected to the main SPEEDBOX unit, where the raw inertial and GPS outputs are combined in real time to accurately measure vehicle attitude (roll, pitch, yaw), acceleration, velocity, distance, gradient and heading as well as position. All measurements have a very low latency of just a few milliseconds, and are output at a rate of 200Hz with no interpolation. The dual antenna setup allows for very precise measurements between the two antennas (to within a few mm) so the yaw and pitch angle of the vehicle can be measured to a few tenths of a degree.

The 200Hz update rate is very important when accurately measuring vehicle responses during testing, assuring the data is accurate during dynamic manoeuvres. With such high update rates on the data it is important not to introduce noise into the system, especially when measuring velocity. The whole SPEEDBOX range is optimised for automotive testing - with the INS options offering the highest accuracy and 200Hz outputs on all channels - ensuring the update rates are as high as possible without introducing noise into the measurements.

The SPEEDBOX-INS is suitable for detailed analysis of driver / circuit / vehicle handling, performance testing, brake and tyre testing, fuel economy, speed verification, development of driver assistance systems etc.

The SPEEDBOX unit outputs the data, for logging and live tests. The data can be logged to a Race Technology logging system, or integrated into an existing system using the SPEEDBOX CAN, RS232, pulse and analogue outputs.

What are the advantages of the INS system?

The system differentiates itself from any similar system in 2 key areas, it's simpler to fit and use, and more economical than competitor systems.

While other systems can take 30 minutes to fit into a car and require relatively detailed configuration, the SPEEDBOX-INS systems can be fitted and outputting data within a few minutes. There is no complex "initialisation" phase required, and the INS Compact Dual Antenna system can initialise whilst stationary, ready to test from “cold” in just a few minutes. For the INS Single Antenna a short drive is requires to converge the system ready for testing, typically this a just a warm up lap or a few corners.

Finally, the system breaks new ground in terms of price / performance compared with similar systems – a SPEEDBOX-INS system is comparable to competitor's price for a GPS only system, but the performance is far superior:

|

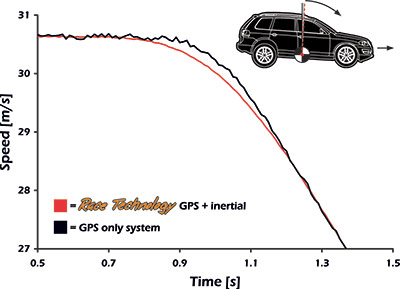

No Speed Overshoot

|

|

|

During brake testing a GPS-only system suffers from speed overshoot, as the brakes are applied the vehicle pitches and the roof mounted GPS antenna accelerates forwards. The time difference as the car decelerates past 100km/h (27.78m/s) and triggers the start of the test is only a few milliseconds (15-20ms), but at 100km/h the distance travelled in a few milliseconds is significant (~0.5m). The SPEEDBOX-INS allows the measurement point to be accurately offset to the centre of gravity giving a true speed measurement with no overshoot. The inertial sensors accurately measure pitch and rotation rates to the reference point achieving unbeatable accuracy of just a few cm for all automotive braking tests. |

|

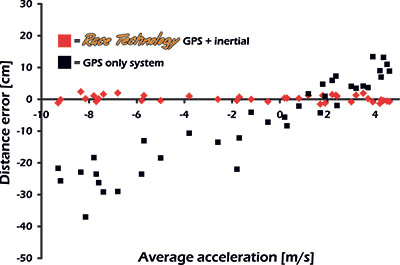

Consistent High Accuracy Results

|

|

|

The SPEEDBOX-INS gives consistent high accuracy measurements under all testing scenarios. Measurements are precise and unaffected by accelerations and decelerations; vehicle pitch, roll and yaw. |

|

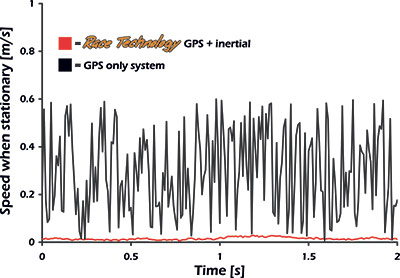

Low Speed Noise

|

|

|

Low speed tests provide the toughest challenge to the accuracy of non-contact speed measurement systems. Errors often show up as high noise when stationary. Many manufacturers remove this noise by implementing a crude zero-clamp on the output, so it is impossible to see any data below 0.5m/s, for example. This is a particular problem with all GPS only speed sensing systems as speed errors at rest are normally significantly higher than speed errors when moving. |

What good is a measurement if you have no idea how accurate it is?

All SPEEDBOX-INS products continuously monitor their own performance and report the maximum error for each braking test. The maximum error is calculated based on many factors, including GPS quality, using an advanced statistical model. After each brake test the system reports both the braking distance and maximum error, for example 42.33m braking distance and +/-3cm maximum error. Engineers and QA Managers can now for the first time be certain that results are valid and measured to an acceptable standard.

Test results can be displayed live in a vehicle using a DASH4PRO display. The SPEEDBOX-INS can be supplied with a data logger and display as part of the CATS-INS integrated system. All triggered tests recorded using one of our Data loggers are stored as both as logged data for further analysis, and test results as human readable ASCii text file.

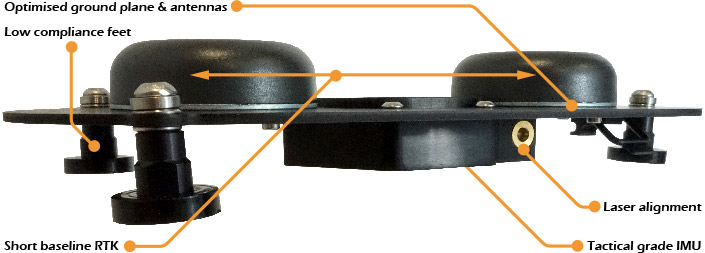

INS Compact Dual Antenna

| Product Datasheet |

The INS Compact Dual Antenna offers the same headline features and accuracy as the INS Single Antenna, however the second antenna allows the system to fully converge on a stationary vehicle.

The stationary convergence allows for “from cold” tests and use on slower, low-dynamic vehicles like mining, farming or military vehicles. Stationary convergence should take a few minutes with good GPS reception, so the whole system can be installed and ready to test in just a few minutes.

SPEEDBOX-INS Compact Dual Antenna additional features:

- Fitted and test ready in a few minutes: Install, Converge, Test! Converges whilst vehicle is stationary with a GPS lock - No figure of eights, no special convergence procedure.

- Laser alignment on vehicle for more accurate installation

- Lower compliance mounting to reduce vibration noise

Basket (0)

Basket (0)